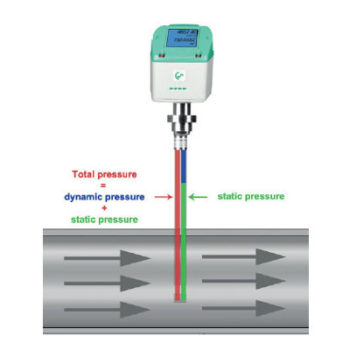

The integrated, precise differential pressure sensor measures the differential pressure/ dynamic pressure at the sensor tip. The pressure depends on the respective gas velocity. The flow is therefore easy to determine by means of the pipe diameter.The additional measurement of temperature and absolute pressure and calculation of the relevant density means that measuring can be carried out for various gases, a wide variety of temperatures and pressures.

Field of application:

- Measurement downstream of the compressor

- Measurement at high temperatures

- Measurement of fast processes

Benefits at a glance:

- Particularly suitable for extremely high flow rates

- Extremely fast response time: 100 ms

- Flow, total consumption, temperature and pressure

- Measurement at high temperatures, max. temperature 200 °C

- Measurement in various gases by selecting gas type, on request

- Can be used in pipes from DN 20 to DN 500

- Installation via 1/2″ ball valve under pressure

- RS 485 interface (Modbus-RTU), 4…20 mA, pulse output as standard

Typical applications:

- FAD measurement of compressors

- Compressed air audits

- Efficiency measurement of compressed air systems